Terracotta floor: how to lay it easily

Simple , honest , we can also say“ down to earth ”thanks to its unpretentious lasting charm, the old terracotta floor enjoys extreme longevity and a timeless charm.

A material as old as human history, the first kilns used for brick firing date back to 3000 BC. The advantages of the terracotta floor were first understood by the Romans , who as early as the 5th century BC. they began to bake clay bricks and from the third century. B.C. during the imperial age they extended the use of bricks to walls and floors, as well as to roofing buildings with tiles. In the second century. A.D. the production of terracotta reached the highest levels of quantity and quality, as witnessed by the countless examples of bricks branded on the back with the symbol of the place of production. This material has remained intact until today, after thousands of years the works of the greatest architects in history, the Romans, remain intact.

About the typical marking on the back of the Roman bricks, Eco Ceramica was inspired by this ancient tradition for the Terra Madre collection, on the back of these 4 cm thick tiles there is in fact imprinted the production mark . Download the Terra Madre catalog for further information.

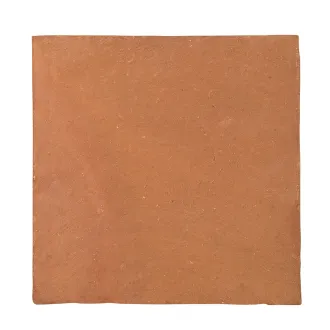

Eco Ceramica terracotta floors are made in hand through the same traditional techniques that are handed down from generation to generation. The purest clay is extracted from specific areas where the earth guarantees a high quality, it is then mixed with water and kneaded by hand. This phase, in which the tile is manually shaped inside the mold, guarantees that the indelible human imprint is fixed, thus making each tile unique and unrepeatable in shape and size. Each piece is dried for 20 days over sand or sawdust, in order to allow natural shrinkage without breaks or cracks.

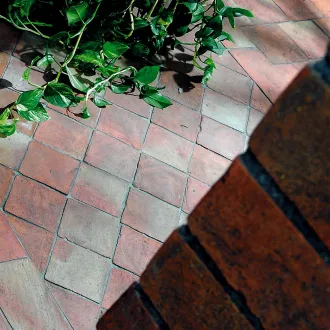

The cooking takes place in a wood oven for 30 hours at 1050 °. The various shades of red and pink typical of our terracotta floor, never the same and repetitive, but rich in natural shading , are precisely due to wood firing. In fact, in the oven the tiles are placed on many shelves, in which the temperature varies slightly, generating a splendid variety of tones.

Once the cooking is complete, the terracotta of the collection Ecological is pretreated with two types of treatments in order to make it water- and oil-repellent. Thanks to this treatment, our handmade terracotta is laid like a normal stoneware tile.

Being pre-treated, in fact, no specific products are required for installation or any post treatment. -posing. Each piece is marked on the back in order to facilitate even more the work of the installer, it is finally cleaned, selected, carefully boxed and delivered on pallets.

Being a product entirely handmade artisanally , therefore not an industrial product, each piece is a unique creation that blends harmoniously with the set of varieties of shades, shapes and sizes.

Here is how to lay a terracotta floor quickly and easily thanks to our tiles from the Ecologica series, visit our Shop for more information on formats and to see some settings of our terracotta.

Watch the video to see firsthand the production of our handmade terracotta!

.jpg)

Comments (0)